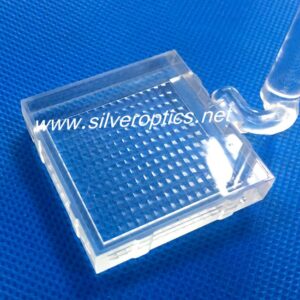

Optical,Transparent,clear Mold&Parts Specifications;

optical light guide

GPTMOLD have rich experience in Optical lenses mold, such as Led lens, spheric and aspheric lens, camera lens, light guide, eye protection, HUD display, Google glass, monitor cover,ect.

High Class optical injection mod manufacturing qualification are as below:

- Import high optical raw material:Zeonex 480R, 350R, 35R, PC, PMMA.

- Core &Cavity Steel:Germany Formadur 2083 ESR,2190 ESR ,Finkl 420 VAR, Formadur PH X supra,

- Mold Base:A&B plate always use P20(28~32HRC)

- Heat Treatment :50~52HRC quenching.

- Surface Finish:SPI A1 or Diamond Turning

- Cavities:2 or 3, or 4,8 12, 16, 24;

- Injection Runner&Gate:Cold Runner Side gate or hot Sprue switch cold sub runner side gate

- Quality:Strict Inspected by Optical Industrial ISO 10110 Optical Inspection Specification;

- Mold Design:Experienced mold designed always know how to make inserts for the optical lens mold, this can ensure the tooling process are easily meet the final requirement.,such as turning, EDM, Polishing, venting. Each step should be carefully considered to reach the final perfect product.

- Cooling system:to meet the optical effect of the molded part, the mold always will need be heated to 90 degree or above