The GPT Mold is a developer and producer of plastic optics;We have years of expertise in meeting technical challenges of all kinds with cost-effective solutions. We cover the entire value chain – from customer demand, the ultra-precision tool-making up to serial production including optical coating.

The GPT Mold is a developer and producer of plastic optics;We have years of expertise in meeting technical challenges of all kinds with cost-effective solutions. We cover the entire value chain – from customer demand, the ultra-precision tool-making up to serial production including optical coating.

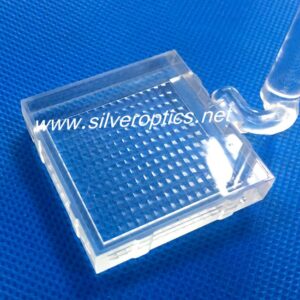

Optical/Transparent/clear Mold&Parts SpecificationsOptical Lens,Optical Mold Manufacurer

We have rich experience in Optical product mold, such as Led lens, light guide, monitor cover,ect.

High Class injection mod manufacturing qualification are as below:

Import high optical raw material: Zeonex 350R,

Core &Cavity Steel: Germany Formadur 2083 ESR

Mold Base: A&B plate always use P20(28~32HRC)

Heat Treatment : 50~52HRC quenching.

Surface Finish: SPI A1 or Diamond Turned

Cavities:6

Injection Runner&Gate:Cold Runner Side gate

Quality:Strict Inspected by each process;

Mold Design:Experienced mold designed always know how to make inserts for the optical lens mold, this can ensure the tooling process are easily meet the final requirement.,such as turning, EDM, Polishing, venting. Each step should be carefully considered to reach the final perfect product.

Cooling system:to meet the optical effect of the molded part, the mold always will need be heated to 90 degree or above

Our Competencies:

Optical Design, Precision Optical Mold Making, Optical Molding, and Optical Coating.

Our Product Lines:

Aspheric condenser lenses, fire polish aspheric lenses, optical filters glass, achromatic lenses, large optical lenses, front surface mirrors, prisms, cylindrical lense. Flat lenses, convex, concave ,Honeycomb mirror, Fresnel lenses