DFM Design for manufacturability

Design for manufacturability (also sometimes known as design for manufacturing)- (DFM) is the general engineering art of designing mold in such a way that they are easy to manufacture. The basic idea exists in almost all engineering disciplines, but of course the details differ widely depending on the manufacturing technology.

Basic DFM for Mold Tooling Project are Included:

- Part Revew with Mold Shrinkage Proposal;

- Partingline Proposal for cavity&core and sliders

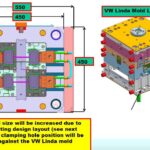

- Mold Layout Propolsa;

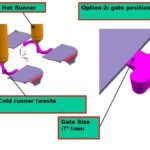

- Gating Proposal;

- Mold Draft Analysis;

- Cavity&Core Inserting Proposal

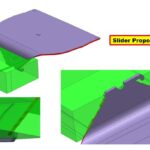

- Slider&lifter Proposal

- Ejection Proposal

- Part Thickness Analysis

- Part Finish&Textures Proposal

- Part Markings Proposal

- Trial Resin and Samples

The design stage is very important in injection mold design. Most of the mold lifecycle costs are committed at design stage. The mold design is not just based on good design but it should be possible to produce by manufacturing as well. Often an otherwise good design is difficult or impossible to produce. Typically a design engineer will create a model or design and send it to manufacturing for review and invite feedback. This process is called as design review. If this process is not followed diligently, the product may fail at manufacturing stage.

DFM PARTINGLINE

This design practice not only focuses on the design aspect of a part but also on the produciability. In simple language it means relative ease to manufacture a mold or assembly.

In the realm of product design and mold manufacturing, the Design for Manufacturability (DFM) process is a crucial step towards ensuring a successful product launch. Before embarking on an official design phase, it is imperative to send the DFM to the customer for validation and feedback. This ensures that all critical elements of the design are in alignment with the customer's expectations and requirements.

One of the most crucial aspects that need confirmation from the customer is the parting line. The parting line, essentially, defines the interface between the mold's two halves, determining how the product will be separated after molding. It is essential to ensure that the parting line is both aesthetically pleasing and functional, minimizing any potential weak points in the final product.

Another key consideration is the gating position. The gate is the point where the molten material enters the mold cavity, and its placement can significantly affect the quality of the molded part. It is crucial to collaborate with the customer to determine the optimal gating position, ensuring that the material flows smoothly and uniformly throughout the mold cavity.

Draft analysis is another crucial aspect of DFM that requires customer confirmation. Draft refers to the angle at which the mold cavity walls are inclined, facilitating the ejection of the molded part from the mold. It is essential to conduct a thorough draft analysis to identify any potential issues that could hinder the ejection process.

Sliders and other mechanisms are also integral to the mold design and require customer validation. Sliders, for instance, are used to create undercuts or overhangs in the molded part, adding complexity to the mold design. It is crucial to collaborate with the customer to determine the best approach for implementing these mechanisms, ensuring that they function seamlessly and efficiently.

Ejection method is another crucial aspect of mold design that requires customer approval. The ejection method involves the means by which the molded part is removed from the mold cavity. There are various ejection methods available, such as push-rod ejection, stripper plate ejection, and so on. It is essential to discuss and finalize the ejection method with the customer, ensuring that it is suitable for the specific application and requirements.

Lastly, it is common practice to propose changes to the part design to optimize the mold design. These changes could involve modifying the geometry, adding draft angles, or altering the material selection. It is essential to communicate these proposals to the customer, discussing their feasibility and potential impact on the final product.

In conclusion, sending the DFM to the customer for confirmation is a crucial step in the mold design process. It ensures that all critical elements of the design are in alignment with the customer's requirements and expectations.

By collaborating closely with the customer, resolving any potential issues, and optimizing the design, we can ensure a successful mold design and product launch.